Letterpress / Embossing

A historic but consistently good method that is once again becoming in demand

Another printing technology that the REPRESS Hodonín printing house has been using since the beginning of its activity (1992) is classic letterpress printing – printing from above. This printing technology enables the production of quality products and special operations. The letterpress machine is no longer a common equipment of printers and advertising agencies. It requires a highly skilled operator and service, but on the other hand it gives great results.

When Johann Gutenberg invented this printing from a height, originally known as mechanical text reproduction, in the mid-fifteenth century, he had no idea how the letterpress method would improve and expand technologically and what it would make possible. This is why letterpress is one of REPRESS‚s main technological directions. It is ideal for special prints of smaller print runs, as well as embossing, thermal cutting, die-cutting, numbering, perforation or some bookbinding work.

Letterpress – the possibilities are wide

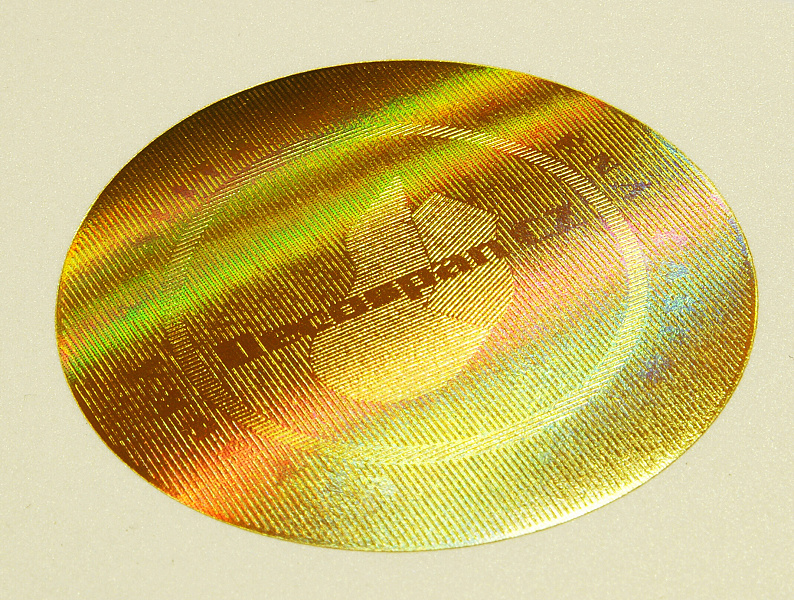

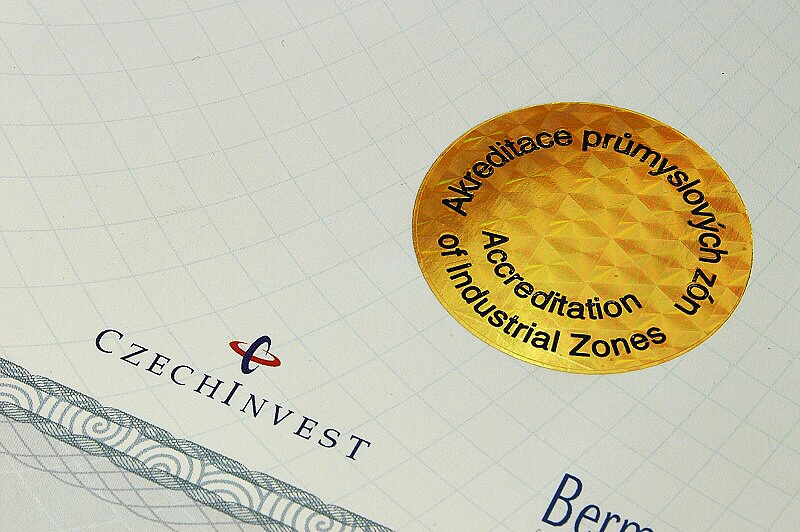

For printing text, lines or graphics, embossing and thermal embossing, a printing form called a plate-stamp is used, made of high-quality metal material or special plastic, which is pressed onto the surface after the ink is applied. Thus, the basic letterpress method is to print in colour and to imprint sheets, from a single colour to a precise offset or multi-colour reproduction. It also allows printing with Pantone spot colours. A spectacular option offered by letterpress printing is iris printing, i.e. the transition of colours. So-called blind or relief printing allows deep or high embossing into the material. A special kind of printing is thermal printing (also called thermal printing, embossing, hot stamping, hot embossing, gold printing, blind printing or 3D embossing), i.e. printing the material with a special film (metallic, pigment or special holographic) using heat and pressure. A hologram can also be applied in this way using an optical sensor and reader.

We can print paper, foil, self-adhesive film, cardboard or other materials up to 350×570 mm. We have no problem with paper from the minimum used weight of 56 g/m2, up to a thickness of 2 mm, or up to a weight of 600 g/m2. We have classic surface-to-surface and surface-to-roll technology, where significantly higher printing pressure is achieved.

Not only printing, but embossing, thermal stamping, hot stamping, gold printing, blind printing, die cutting, creasing, numbering…

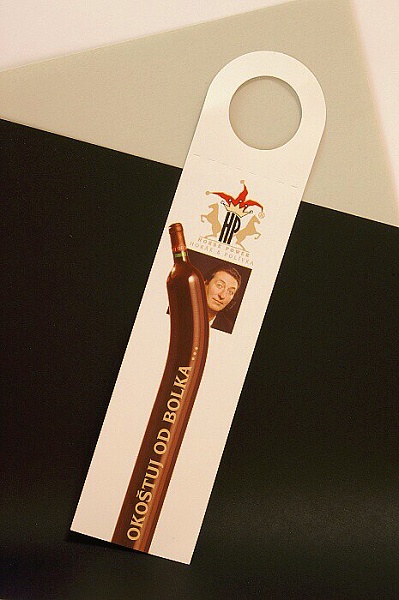

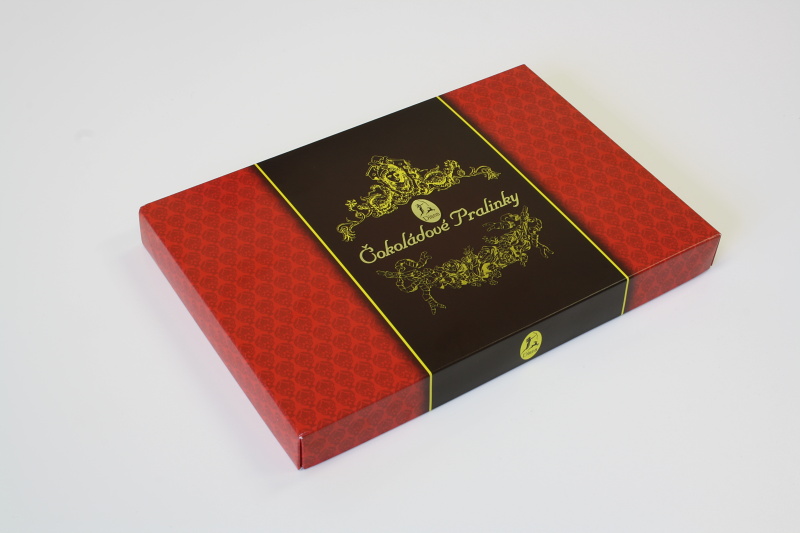

In addition to the aforementioned printing in colour, embossing andthermal stamping are popular, and letterpress is well suited for this. Your business card or perhaps a cover or invitation will be interestingly distinctive and different. Our experience and the interest of our customers make thermoforming particularly suitable for the production of wine labels and medals and graphic accessories for printed materials. A wine label, whether paper or self-adhesive PVC film, with thermal cutting has an exclusive effect. But this is not the end of our possibilities.

We can cut any shape, from labels to cardboard. We can also number your printed materials. Perforation or creasing is a common operation.